Soldering is a fundamental technique in electronics and various other fields, enabling the joining of metal components to create reliable electrical connections. To achieve successful soldering, a range of tools is used to ensure precision, safety, and efficiency. Below, we explore the essential soldering tools, their functions, and their importance in the soldering process.

Soldering Iron

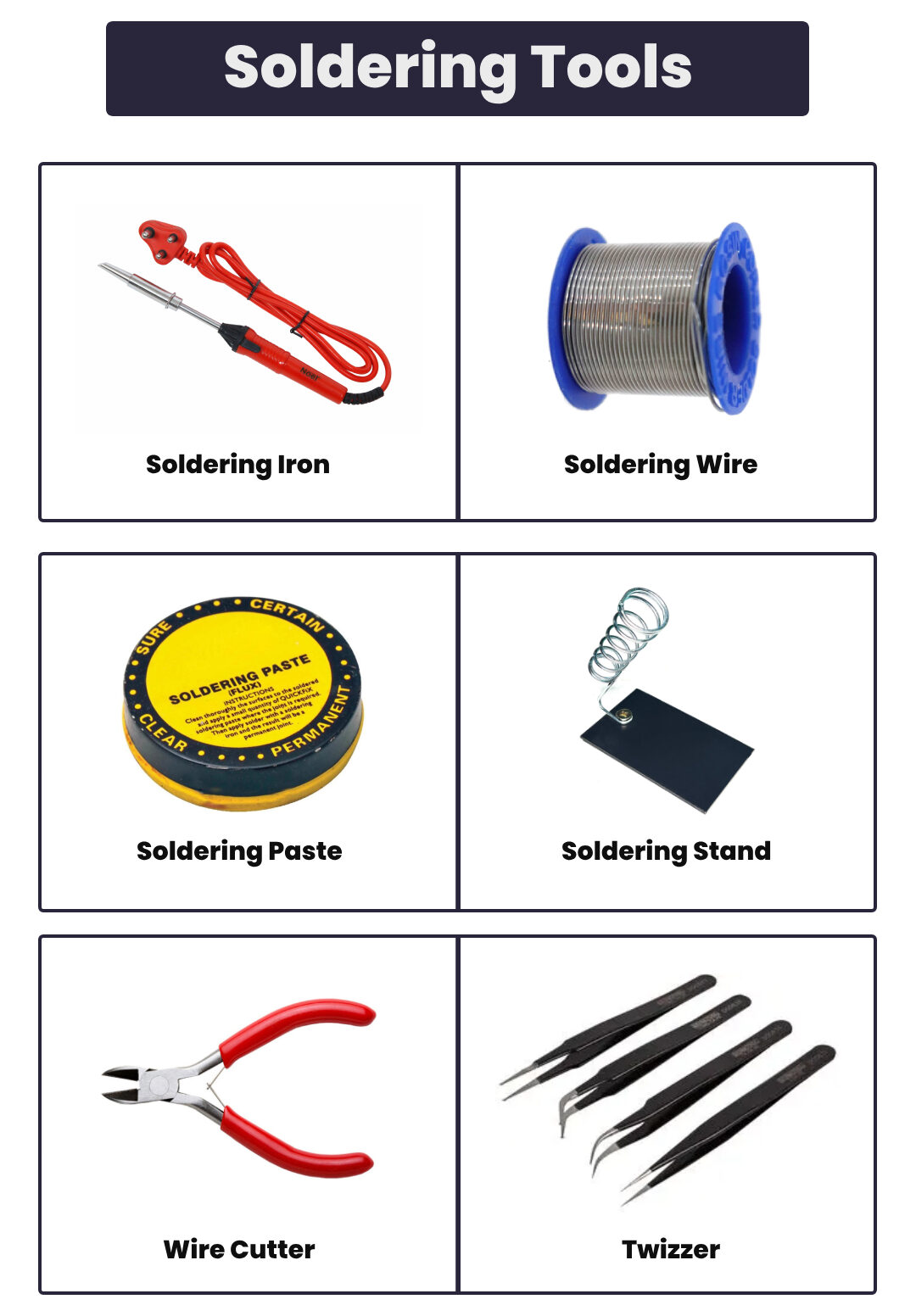

The soldering iron is the most basic and essential tool for soldering. It is a handheld device with a heated metal tip used to melt solder. Soldering irons come in various power ratings, typically ranging from 15W to 60W, with higher wattage providing faster heating and better performance for larger components.

- Features: Ergonomic handle, replaceable tips, temperature control (in some models)

- Usage: Suitable for most basic soldering tasks, including wire connections and small electronic components.

Soldering Station

A soldering station is a more advanced setup that includes a temperature-controlled soldering iron and often additional tools such as a desoldering pump. The temperature control feature allows for precise regulation of the soldering iron’s heat, which is crucial for working with sensitive components.

- Features: Adjustable temperature control, digital display (in some models), interchangeable tips

- Usage: Ideal for professional electronics work, repetitive soldering tasks, and projects requiring precise temperature settings.

Solder

Solder is a fusible metal alloy used to join metal workpieces. It typically comes in wire form and melts when heated by the soldering iron, creating a strong electrical and mechanical bond.

- Types: Lead-based solder (tin-lead), lead-free solder (often tin-silver-copper)

- Usage: Choose solder based on the application and regulatory requirements. Lead-free solder is now more commonly used due to health and environmental concerns.

Flux

Flux is a chemical cleaning agent that removes oxidation from metal surfaces, ensuring a strong bond between the solder and the components. It comes in various forms, including liquid, paste, and flux-cored solder wire.

- Types: Rosin flux, water-soluble flux, no-clean flux

- Usage: Apply flux to the joint before soldering to improve the flow and adhesion of the solder.

Desoldering Pump

A desoldering pump, also known as a “solder sucker,” is used to remove solder from a joint. It creates a vacuum to suck up the molten solder, allowing components to be separated and removed from the circuit board.

- Features: Spring-loaded plunger, replaceable tips

- Usage: Essential for rework and repair tasks, particularly when replacing components on a PCB.

Solder Wick

Solder wick, or desoldering braid, is a braided copper wire coated with flux. It is used to remove excess solder from a joint by capillary action. The solder wick absorbs the molten solder when heated with a soldering iron.

- Features: Various widths, flux-coated

- Usage: Effective for cleaning up solder joints and removing bridges between closely spaced pins.

Third Hand Tool

A third hand tool is a stand with adjustable arms and alligator clips used to hold components in place while soldering. It provides stability and frees up the user’s hands, making the soldering process easier and more precise.

- Features: Adjustable arms, magnifying glass (in some models)

- Usage: Ideal for holding wires, circuit boards, and small components during soldering.

Heat Gun

A heat gun is used to apply heat to shrink tubing or to assist in the removal of components. It generates a stream of hot air that can be directed at specific areas, making it useful for various soldering and desoldering tasks.

- Features: Adjustable temperature, different nozzle attachments

- Usage: Useful for heat-shrink tubing, soldering heat-sensitive components, and desoldering large components.

Soldering Mat

A soldering mat is a heat-resistant mat used to protect the work surface while soldering. It prevents damage to the workbench and provides a safe area for soldering tasks.

- Features: Heat-resistant, non-slip surface

- Usage: Essential for protecting work surfaces from heat and solder splashes.

Soldering Tips

Soldering tips are the replaceable parts of a soldering iron that come into direct contact with the solder and components. Different tip shapes are available for various soldering tasks.

- Types: Conical, chisel, bevel, and specialty tips

- Usage: Select the appropriate tip shape based on the specific soldering task to ensure optimal performance and precision.

Soldering Iron Stand

A soldering iron stand is used to safely hold the soldering iron when not in use. It often includes a sponge or brass wool for cleaning the soldering tip.

- Features: Stable base, tip cleaning element

- Usage: Keeps the soldering iron secure and helps maintain the cleanliness and longevity of the tip.

Soldering Fume Extractor

A soldering fume extractor is used to remove harmful fumes generated during the soldering process. It uses a fan to draw the fumes through a filter, providing a safer working environment.

- Features: Adjustable suction, replaceable filters

- Usage: Essential for protecting health by reducing exposure to toxic soldering fumes.